Summary

Gnuman requires 3 position

encoders and 3 velocity encoders. The

velocity encoders are already on the robot and use incremental encoders. As for the position encoders that require an

absolute position (independent of power cycles), Incremental encoders with a

home/zero position make the most sense.

While Synchros, Resolvers, and Absolute encoders would suffice, the cost

can be as much as 7-8 times more expensive.

The benefits of having a Resolver/Synchro able to operate in extreme

conditions, be more durable, and more accurate are offset by the price. Likewise, while Absolute encoders provide

digital position data which can be processed more easily, the cost makes it

impractical.

Position control for motors (Rotary Encoders)

A rotary encoder is an electromechanical switch used to measure angular position and angular motion. Its output is generally composed of a digital encoding of relative or absolute position. Specialized rotary encoders called synchros actually output into sinusoidal waves where the phase difference represents the angular position.

Synchros

Synchros

A Synchro is a generic term for a family of

transducing elements. These transducing

elements can be arranged in various ways to measure angular position. The synchro works on the rotating transformer

principle to generate secondary currents from a primary sinusoidal current.

The rotor is an extension of the shaft. Three windings are attached 120 degrees apart

and are connected to the terminals S1, S2, and S3. This type of connection is known as a wye connection. The

windings from the rotor are connected by slip rings and brushes to the

terminals R1 and R2.

An AC voltage, known as the reference voltage (usually

either 60Hz or 400Hz), is sent through the rotor winding and subsequent

voltages are induced in the stator windings proportional to the cos angle (f) between the rotor coil and stator coil. .The voltage induced across any pair of

stator terminals will be the sum or difference, depending on the phase, of the

voltages across the two coils concerned..

Reference voltage: A Sin wt

The voltages which will appear across the stator

terminals will be:

S1 to S3 = A sin wt Sin f

S3 to S2 = A sin wt Sin (f + 1200)

S2 to S1 = A sin wt Sin (f + 2400)

where f is the synchro shaft angle.

Resolvers

The Resolver is a type of synchro, sometimes called

Synchro Resolvers, in which the windings on the stator and rotor are at 90

degrees to each other instead of 120 degrees

as in the case of the general synchro. This allows the Resolver to take advantage of

the sinusoidal relationship between output voltage and shaft angle. Resolvers come in many forms with a wide

variety of winding configurations and transformation ratios. The simplest

Resolver would have a rotor with a single winding and a stator with 2 windings

at 90 degrees to each other.

AC reference voltage: A Sin wt

Then the voltages appearing on the stator terminals

will be:

S1 to S3 = V Sin wt Sin f

and S4 to S2 = V Sin wt Cos f

where f is the Resolver shaft angle.

Optical Encoders

Incremental

encoders

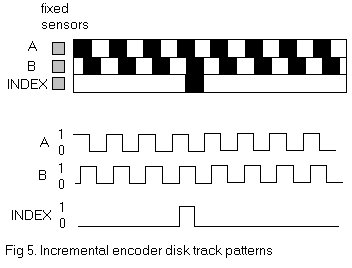

Incremental encoders consist of a disc, light source,

and light detector. The disc is made up

of evenly divided alternating light and dark sectors (ranging from opaque to

transparent) and is attached to the shaft.

The light source is placed on one side of the disc while the light

detector is on the other side. As the

disc turns (upon given rotation from a motor), the detector will detect on or

off depending on which part of the disc is in between the light source and

detector. From this, a square wave pulse

stream is produced. The sum of the

pulses is used to indicate angular position of the shaft and velocity

information can also be extracted based on the resolution. The resolution of the encoder is related to the

number of sectors the disc is divided into.

.The resolution of the encoder is governed by the number of opaque and

transparent sectors and usually falls between 100 and 6000 counts for one

complete revolution of the input shaft..

Almost all incremental encoders have a second light source and detector

which is phased correctly so that the direction of the

rotation can be obtained.

Also, many encoders even included a third light source

and detector which output only once per revolution making velocity measurements

attainable.

.Incremental encoders come in sizes ranging from 1

inch diameter (25.4 mm) to 3½ inches

diameter (88.9 mm). They are also available in all types of

external construction ranging from plastic, which is suitable for low cost

commercial applications, to stainless steel where the required specification is

more rigorous. While this type of encoder may be useful in some applications it

has the disadvantage of having the angular information stored in an external

counter. If the information in this counter is lost (for example if the power

supply was temporarily interrupted) there is no way of knowing the shaft angle.

Also at initial switch on, there is no way of determining the shaft angle until

it has been rotated through the revolution

marker..

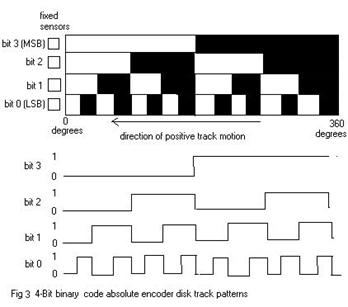

Absolute

encoders

Absolute encoders are very similar to incremental

encoders. Here, the disc is divided into

N alternating dark and light sectors pertaining to a count (based on the coding

scheme). Each count relates to the bit

representation of the absolute position.

For example, for a 6 bit resolution, there will be 6 counts, one for

each bit. Each bit/count has its own

light source and detector. A set of light

sources are arranged radially on one side of the disc

and corresponding detectors are positioned on the other side such that a

parallel word representing the input shaft angle can be obtained at any one of

the angular positions.

Therefore, the absolute position on the disc,

corresponding to the absolute position of the shaft, is always known. Even powering down does not affect the data. .Absolute optical encoders come with

resolutions of 6 to 16 bits in Gray code, binary or BCD and their sizes vary

from 2 inches (50.8 mm) to about 7 inches (177.8 mm) in diameter..

REFERENCES:

http://www.sensorwiki.org/index.php/Rotary_encoder

http://www.feedbackdevices.com/content.aspx?id=43

http://www.evaluationengineering.com/pctest/articles/0399daq.htm

http://amci.com/tutorials/tutorials-what-is-resolver.asp

http://www.analog.com/en/content/0,2886,760%255F%255F97528,00.html

http://en.wikipedia.org/wiki/Resolver_%28electrical%29

http://www.acalmicrosystems.co.uk/pdf/faq/synchrohandbook.pdf.

http://mechatronics.mech.northwestern.edu/design_ref/sensors/encoders.html