Subjugator Generation 1: Background

|

An autonomous underwater vehicle competition was being put

together by the

Association for Unmanned Vehicle Systems International

which was to be held in August of 1996. After

hearing about the competition, a small interdisciplinary group of

university students consisting of mechanical and electrical engineers

got together to design and build a submarine.

Since the rules didn't exist until the end of December, a lot

needed to happen in order to make it in the eight-month deadline.

A proposal was written at the end of January to acquire funds for

the building of the submarine.

Since the rules didn't exist until the end of December, a lot

needed to happen in order to make it in the eight-month deadline.

A proposal was written at the end of January to acquire funds for

the building of the submarine.

The group of students got together to discuss the body shape, the

control, and layout of the components. After about two months of

deliberation on the motor layout, and the consideration of

various body shapes and materials (a pony keg was considered at

one point, hmmm students and beer, go figure), it was decided to

go with something simple (always a good choice).

Four motors were chosen to drive the sub, and they were

positioned so that each pair was orthogonal. The fore and aft

motors were positioned downward to provide vertical motion (z-

translation) and pitch stability. The port and starboard motors

were positioned horizontally to provide forward/backward motion

(x-translation) when the props rotated in the same direction and

rotation (z-rotation) when they were spun at different RPMs. The

body was a simple cylindrical shape for easy of construction, and

reduction of drag.

|

Body

|

With only six months, we set about cutting out the body from the

foam, acquiring the hardware, and building the electronics. For

strength, the motors were attached to the body through steel

tubing.

The volume require to float the various components was

calculated, and the body was cut to rough size. Once the pieces

were in place, the body was smoothed out, and the glass material

was laid on top.

Two clear 10.16 cm acrylic tubes were added to house the various electronics

(clear, so that we could see when something went wrong (not that it ever

did, oh no...). One of the tube endcaps was made from aluminum to serve

as a heat sink for the motor drivers.

|

For roll stability, the weight (mostly the battery) of the sub

was placed low, while the buoyancy was placed higher up. This

allowed the sub to maintain roll (and some pitch) stability due

to the moments created by these two forces.

|

Power and Propulsion

|

An Exide 12V Gel cell battery supplies power for the motors. A separate

power supply, housed within the acrylic tube, is used for the electronics.

The electronics are optically isolated to minimize coupling between the

electronics and the electrical noise from the motors.

An Exide 12V Gel cell battery supplies power for the motors. A separate

power supply, housed within the acrylic tube, is used for the electronics.

The electronics are optically isolated to minimize coupling between the

electronics and the electrical noise from the motors.

|

Four Minn Cota motors are used for propulsion. Each motor provides 24

pounds of thrust. Two are fixed vertically, fore and aft, and provide

pitch stability and ascent/decent thrust. The other two are fixed

horizontally, port and starboard, and provide forward/backward thrust,

and turning thrust.

Four Minn Cota motors are used for propulsion. Each motor provides 24

pounds of thrust. Two are fixed vertically, fore and aft, and provide

pitch stability and ascent/decent thrust. The other two are fixed

horizontally, port and starboard, and provide forward/backward thrust,

and turning thrust.

|

Mechanics

|

Since the competition called for picking up an object, we worked

on a buoyancy control system consisting of air tanks, a buoyancy

compensator and an air valve. The initial buoyancy compensator

was a large flower pot. It later progressed into a clear 17 inch

salad bowl. The two spare air tanks ran into a regulator to drop

the pressure. This regulated pressure was split, one half ran through

a solenoid to an air actuated valve to fill the compensator with water,

the other ran through a solenoid to fill the compensator with air.

|

Electronics and Sensors

|

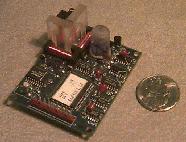

H-bridge Motor Driver

The original H-bridge motor drivers were from Motorola. They proved to be

a little on the sensitive, and hard to come by since Motorola stopped

manufacturing them.

From there, a new motor driver was designed and built using discrete

components.. [more detail here]

|

Digital Compass

The

Precision Navigation TCM2 digital compass is a high-performance,

low-power electronic compass sensor that outputs compass heading, pitch,

and roll readings via electronic interface to a host system. It is based

upon a proprietary triaxial magnetometer system and a biaxial electrolytic

inclinometer, and contains no moving parts.

|

Pressure Sensor

The Omega PX180

pressure sensor measures 0-30 PSIG in millivolt range. The silicon

sensor is bonded on a glass pedestal to isolate it from induced stresses,

provides wide media compatibility, and the stainless steel pressure port

permits use with corrosive substances.

|

Digital Camera

The Connectix color Quickcam (now logitech) is

capable of up to 24 frames per second or a 320 x 240 image. The parallel

port connection makes it possible to connect this piece of hardware to

any board with a parallel port (that, and some good bit of coding).

|

Low-level Control

|

A motorolla 68HC11 was chosen to interface to all of the sensors and

to drive the motors. The code was written in assembly language.

Originally, input from a R/C joystick was translated into sub movements.

The user had total control of the horizontal thrust motors, and the

solenoids for the buoyancy control. The user could "dial-in" a depth

from the joystick, and the sub would seek that depth. This added in

shaking out some problems in controlling the sub autonomously.

The commands from the joystick to the motors were converted to

a direction and a Pulse Width Modulated (PWM) signal. Pitch data from

the compass was integrated to stabilize the sub as it moved around.

Depth was calculated from the pressure sensor and compared to the desired

depth.

|

High-level Software

|

To complete the transition to a fully autonomous sub, the original

68HC11 was replaced with one which had 32K of RAM so that the code

could be written in C.

On startup, the submarine would turn the z-axis motors on to drive

the sub down while opening the air-valve to fill the buoyancy compensator.

This would get the sub neutrally buoyant. Form there, it would dive to

the desired depth and maintain that depth while trying to travel a

constant heading taken from the compass.

The color camera would then be used to find and navigate toward the

gates. The camera image would be analyzied to find the outline of the

gate, and then the sub would drive torward the centroid.

|